Per generazioni, gli apicoltori hanno considerato i opercoli di cera come semplici sottoprodotti dell'estrazione del miele. Eppure, questi sottili strati di cera racchiudono un potenziale inespresso: la loro trasformazione può aumentare la sostenibilità *e* le entrate. Questa guida rivela metodi pratici per riutilizzare i opercoli, supportati da tecniche di lavorazione comprovate e applicazioni commerciali.

Il Ruolo dei Opercoli di Cera nella Produzione di Miele

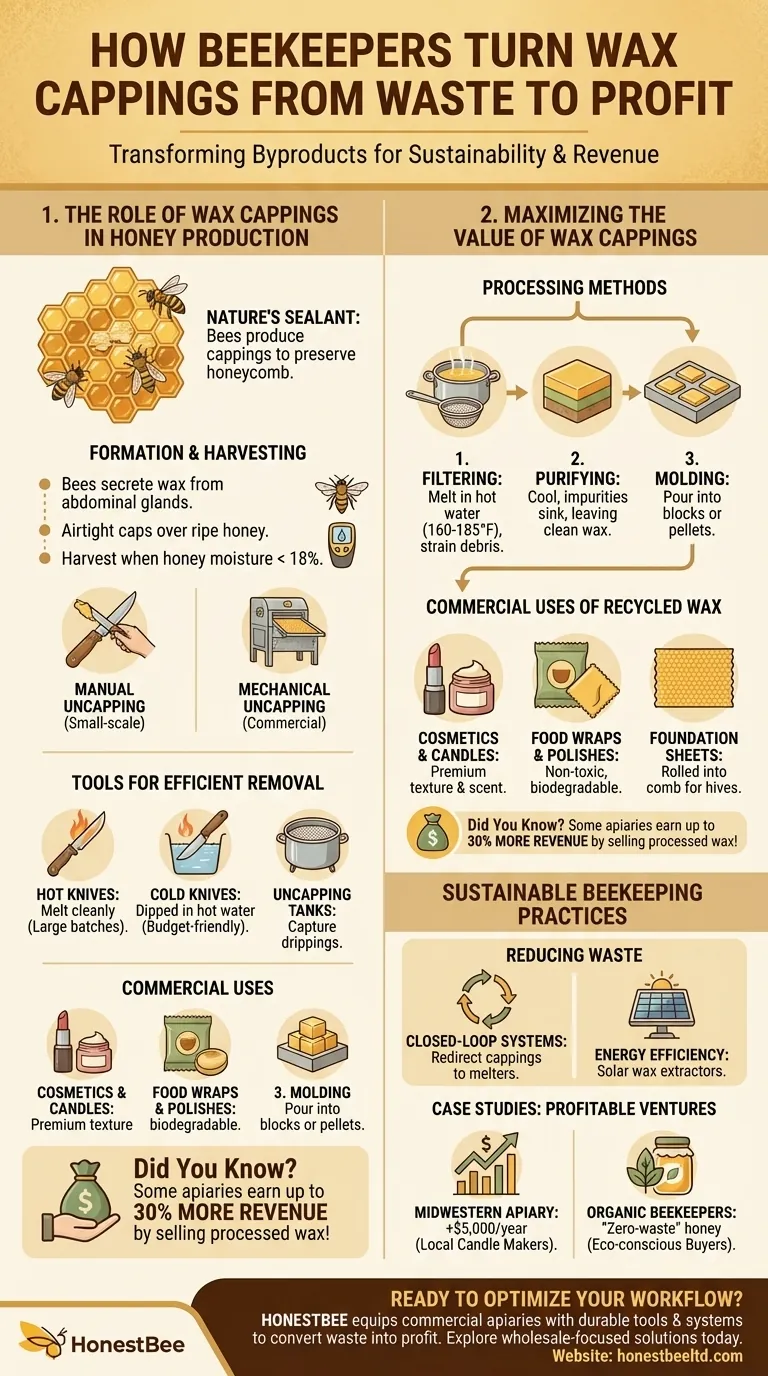

I opercoli di cera fungono da sigillante naturale: le api operaie li producono per conservare le celle dei favi. Durante la raccolta del miele, la rimozione di questi opercoli è il primo passo, ma scartarli significa sprecare un materiale ricco di risorse.

Come si Formano e si Raccolgono i Opercoli di Cera

Le api secernono la cera dalle ghiandole addominali, modellandola in tappi ermetici sul miele maturo. Durante l'estrazione:

- Il tempismo è importante: i opercoli sono più facili da rimuovere quando il livello di umidità del miele è inferiore al 18%.

- Metodi di raccolta: disopercolatura manuale (comune per operazioni su piccola scala) o disopercolatura meccanica (per apiari commerciali).

Strumenti e Tecniche per una Rimozione Efficiente

Strumenti adeguati minimizzano gli sprechi e mantengono la qualità della cera:

- Coltelli a caldo: lame riscaldate elettricamente fondono i opercoli in modo pulito, ideali per grandi lotti.

- Coltelli a freddo: economici ed efficaci se immersi in acqua calda per ridurre l'attrito.

- Vasche per disopercolatura: catturano le gocce per una successiva lavorazione.

Consiglio Pro: Abbina gli strumenti a un rullo o un'affettatrice per disopercolare per accelerare il processo.

Massimizzare il Valore dei Opercoli di Cera

I opercoli lavorati producono cera d'api di alta qualità, una merce con mercati diversificati.

Dalla Pulizia alla Cera d'Api: Metodi di Lavorazione

- Filtrazione: sciogliere i opercoli in acqua calda (70–85°C), quindi filtrare attraverso una garza per rimuovere i detriti.

- Purificazione: lasciare raffreddare la cera; le impurità si depositano sul fondo, lasciando uno strato superiore pulito.

- Stampaggio: versare la cera purificata in blocchi o pellet per la conservazione o la vendita.

Usi Commerciali dei Opercoli di Cera Riciclati

- Cosmetici e candele: la consistenza e il profumo naturali della cera d'api comandano prezzi premium.

- Involucri alimentari e lucidanti: alternative non tossiche e biodegradabili ai prodotti sintetici.

- Fogli di fondazione: la cera riciclata può essere arrotolata in fogli di fondazione per gli alveari.

Lo sapevi? Alcuni apiari guadagnano fino al 30% in più di entrate vendendo cera lavorata insieme al miele.

Pratiche Apistiche Sostenibili

Il riutilizzo efficiente dei opercoli si allinea alla gestione ecologica dell'apiario.

Ridurre gli Sprechi nell'Estrazione del Miele

- Sistemi a ciclo chiuso: reindirizzare i opercoli nei fusori per cera invece che nei bidoni dei rifiuti.

- Efficienza energetica: gli estrattori di cera solare riducono i costi del carburante durante la lavorazione.

Casi di Studio: Imprese Redditizie di Opercoli di Cera

- Apiario del Midwest: ha aggiunto $ 5.000 all'anno fornendo a produttori locali di candele cera raffinata.

- Apicoltori biologici: commercializzano miele "a zero sprechi", attraendo acquirenti attenti all'ambiente.

Pronto a ottimizzare il tuo flusso di lavoro apistico? HONESTBEE fornisce agli apiari commerciali e ai distributori strumenti di disopercolatura durevoli e sistemi di estrazione, aiutandoti a convertire i rifiuti in profitto. Esplora oggi stesso le nostre soluzioni orientate al commercio all'ingrosso.

Guida Visiva

Prodotti correlati

- Cera d'api a vapore Melter Scaldacera per la lavorazione della cera

- Fonditore di cera d'api per la fabbricazione di candele Fonditore di cera d'ape

- Fonditore di cera professionale in acciaio inox per l'apicoltura e l'artigianato

- Macchina elettrica per il flatting e la goffratura con vassoio per l'apicoltura

- Macchina elettrica per fogli piani di cera d'api con vassoio operativo per la lavorazione della cera

Articoli correlati

- Il Motore Nascosto dell'Alveare: Decodificare l'Economia della Produzione di Cera

- Come sciogliere la cera d'api in sicurezza: preservare la qualità evitando i pericoli

- Il paradosso dell'apicoltore: perché il calore lento sblocca il vero valore della cera d'api

- Come sciogliere la cera d'api in modo sicuro:Metodi esperti per evitare il rischio di incendio

- Come Trasformare la Vecchia Cera d'Api in Prodotti Redditizi e Sostenibili